Request a callback

- Have a question? Leave your number and we'll call you back

Request callbackBuilt to last, our 2 post service lifts are a cost-effective and space-saving solution for any workshop. The range includes mechanical screw and hydraulic models with lifting capacities of up to 7T to accommodate the growing number of larger vehicles.

Our 2 post vehicle lifts are manufactured in Europe and designed and built to the highest standards. Each lift comes with two years’ warranty and you can expect the best advice, support and service from our in-house engineers and comprehensive network of approved distributors located throughout the UK.

In comparison to 4 post lifts, 2 post lifts generally cost less and take up less space making them a popular choice with service garages and automotive workshops. With lifting capacities of up to 7T, the larger models are more than capable of handling the growing number of heavier cars and vehicles and provide the potential for an excellent return on investment.

There are a lot of inferior quality 2 post lifts on the market and in some cases these lifts can pose a risk to safety. In 2015, the UK Health and Safety Laboratory put some typical 2 column vehicle lifts to the test. Worryingly, only 3 out of the 7 lifts tested met the safety standards for the arm locking mechanisms (Source: HSE RR1030 - Assessment of the arm locking systems of two-post vehicle lifts).

The whole range of Boston vehicle lifts meets and often exceeds all UK safety regulations. Should you be considering a lift by any other manufacturer, we strongly advise that you ask plenty of questions before making an investment. The below provides guidance on the key items to consider.

Where is the lift manufactured? Many lifts from the far-east are poorly manufactured with little quality control. Look for a European model from a reputable manufacturer and if unsure, question the quality control processes in place.

CE Certification is a requirement for all vehicle lifts supplied in the EU, but the CE marking is not definitive proof of this as labels can be added fraudulently. If unsure, ask to see the manufacturers certification correspondence and documentation which they are required to keep.

Arm locking mechanisms must be automatic (legal requirement in the UK) and arm locking grooves should be quality machined – check for a smooth finish and cleanly cut burr-free teeth. This will allow the operator to engage and disengage the arm locks without trouble; cheaper models struggle to consistently deliver on this which quickly becomes an annoyance for the person using the 2 post lift, not to mention a safety issue.

Welding is a key item of the lift’s construction. Welding around columns and base plates, arms and extensions, should be neat and penetrate the metal to enforce the join. This is often not the case for sub-standard lifts where welding has not been properly quality controlled. The vast majority of EU manufacturers carry out regular weld penetration tests on their products using special equipment. Again, if unsure ask the manufacturer about their welding quality control processes.

Steel thickness is good indication of the quality of a vehicle lift. When looking at different lifts, check and compare the thickness of the column steel and the floor mounted base plates, both of which should increase as the lifting capacity increases. The overall dimensions of the base plates is also important and should again be in proportion with the lift’s capacity.

When deciding which twin post lift is the right choice for your automotive business, consider the types of vehicles you frequently work on, or plan to work on, to ensure that you select the appropriate lifting capacity. If in doubt, and you have the space, it’s worth looking at the larger models as they provide the opportunity to work on a greater range of vehicles (this is especially important for service and repairs garages that depend on one or two lifts). You’ll also need to decide between a mechanical screw or a hydraulic powered vehicle lift. There is no right or wrong choice here, both versions are a great addition to any workshop and have their own merits. To help you make this decision, we’ve covered some of the main differences of our two ranges as well as some other points to consider:

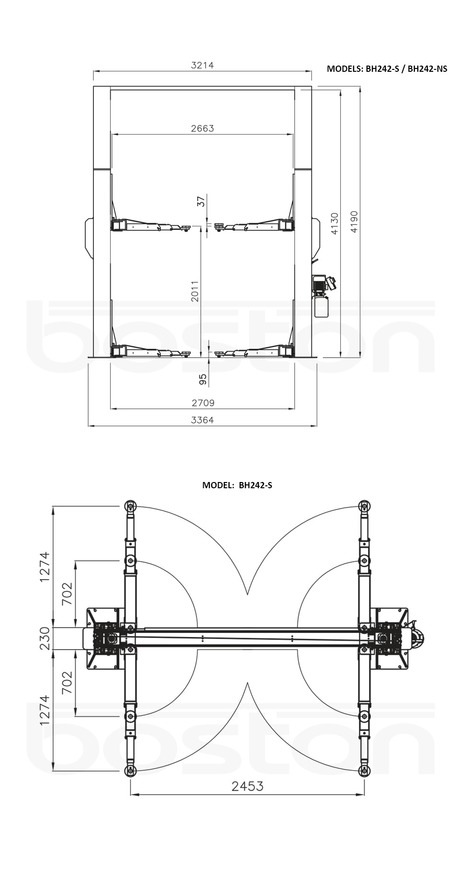

Take a look at our product pages for more details on our range of 2 post vehicle lifts including full specifications and technical drawings. If you require advice or wish to speak to one of our technical experts, give us a call on 01708 525585.

Read more… A guide to Two Post Lifts – Maintenance & Safe Operation